INDIVIDUALITY

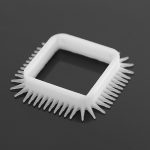

- individual geometry according to your component requirements

- pin diameter, distance, length and arrangement on the circumference can be adapted fastly and easily for greater freedom in component design

- suitable for different core geometries (triangle-, box- or T-profile)

ROBUSTNESS AND PROCESS RELIABILITY

- robust und reliable production

- pins made of special polymer, which withstands the forces and temperature loads occurring during production

- winding pins enable precise placement of rovings and thus the production of components with improved mechanical properties

- optimised programming of the winding machine possible, i. e. exact coordination between winding pins and machine

- damage to the winding core can be avoided during demoulding by using PLA, PA or ABS

FASTNESS

compared to the standard solutions available on the market, our highly innovative snap-in system ensures faster and more cost-effective fixing of the ring to the winding core